The history of forklifts is directly related to the industrial revolution in the 18th and 19th centuries.

For more than 100 years, load-carrying vehicles have been improving in terms of efficiency and weight capacities. What we know as forklifts today started as hand carts and bulky trucks that were nowhere as productive as modern versions.

Contemporary forklifts whizz around warehouses with great agility and are a necessity in industries were moving cargo efficiently is required.

But it hasn’t always been like this. The history of this essential piece of forklift machinery is long and full of interesting occurrences.

Start by listening to our podcast episode on the most interesting things to know on the evolution and use of forck trucks over time, from the beginning to the current time:

Let’s take a look at forklift trucks through history.

Where It All Started: Forklift Trucks Through History

Before any complex mechanised vehicles were conceived, the precursors of forklifts were two-wheeled carts that looked like dollies. Railroad and dock workers mainly used these hand-powered devices to ferry goods on and off freight vessels, thus reducing the grueling work of lifting loads on their backs.

Some of these ‘sack trucks’ had manual hand cranks that allowed users to lift loads a few feet high.

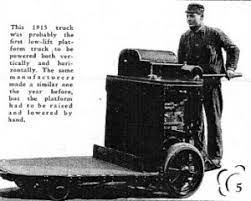

Towards the end of the 19th century, the closest thing to a forklift was built. It was a fork truck with a loading platform that rose just a few inches. The design of this machine was crude, and it couldn’t withstand the rigors of industrial settings.

A steel variant of the basic fork truck was built in 1909, and unlike its forerunner, it was sold commercially. Quite a number of the machines were sold until a ground-breaking upgrade came along.

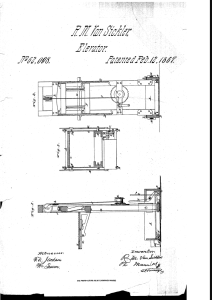

First Patent

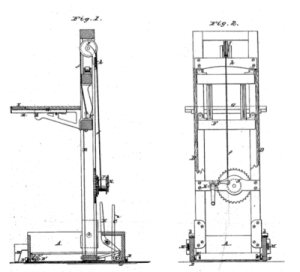

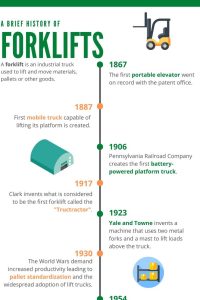

In 1867 a patent was lodged by Van Sicklar for a device known as an Improved Elevator. The machine could move and lift materials using a cantilever platform and a hoisting system.

The invention was meant for stores but could be used on worksites while attached to a cart.

In 1887 the Portable Elevator improved on the earlier model with a more elaborate lifting apparatus. These two simple devices lay the groundwork for the contemporary forklift truck many years later.

Commercial Fork Trucks

During the early 20th century, engineers brainstormed about developing better-specialised vehicles for ferrying shipments within industrial sites.

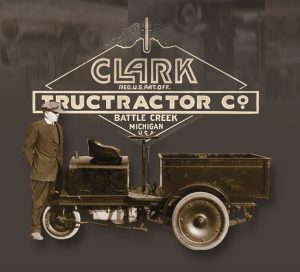

The Clark Material Handling Company is credited with developing the first working prototype named Tructractor. The gasoline-powered truck was a lumbering hulk of metal, but it effectively moved loads within factories and warehouses.

Clark had no intentions of commercialising the Tructractor and only wanted to use them in their axle manufacturing factories.

The news of this new seated counterbalanced truck began to spread, and when Clark noticed the great interest, they stepped up production to corner their market.

Despite having what we now view as a basic design, the Tructractor played a big role in influencing modern forklift design.

Adding More Power

By the 1920s, forklift trucks were improving technologically. There was a greater need to make the trucks more powerful.

Hydraulic parts were added to make it easier to lift loads, especially for those with a mounted crane. Electronic controls were also incorporated to improve operation and handling. This was never seen before in the history of forklifts.

The early versions of forklifts were very slow, requiring more powerful engines to add speed and haulage strength.

The added power resulted in technological alterations, including shorter wheelbases, welded joints, and tilting masts.

Forklift Trucks Through History: Introduction of Lifting Cantilevers

In 1923, Yale University engineers created a lifting mechanism that used a vertical mast or cantilever. The forklift used electrical power to raise the forks and load up the mast.

Many consider the Yale version the first actual forklift. But there was one major problem that hindered this forklift from being accepted universally. The lifting pallets did not always fit the forks well.

Luckily, this problem ended in the 1930s when universal pallet sizes were introduced. Later on, the dimensions of forklifts were also standardised for all manufactured models.

The cantilever forklifts gained more popularity during the Second World War. Armies used them to load armaments and supplies faster due to their improved power and efficiency.

Mainstreaming the Forklift

Once factory owners started buying forklifts in numbers, they became a common feature in industries and warehouses.

Mass production was the next step as prices stabilized and more research and development advanced forklift technology.

There was a massive uptake of forklifts in the post-war era due to their significant role in war efforts.

One issue that stood in the way of immediate market acceptability was the machine’s large size. Engineers worked tirelessly to scale down its size to easily manoeuvre warehouse corridors.

Impact on Wars

The wars made an impact on the history of forklifts. The first and second world wars created a need for efficient transportation of people and materials. The lifting trucks came in handy and soon became a priority.

Another reason that spurred the spread of forklift trucks during wartime was a shortage of labour due to mass army recruitment and numerous deaths on battlefields.

Mechanisation offered ‘‘extra pairs of hands’’ that were greatly needed at that time.

Vertical Warehousing

The post-war period led to an industrial boom and a subsequent demand for warehousing efficiency.

A key strategy was the vertical expansion of warehouses. As forklifts became slimmer and more agile, they could navigate the narrow spaces and stack cargo vertically.

The narrow-isle forklift model still exists due to this warehouse design revolution in the mid-20th century.

Oversight Bodies

The need for regulation led to the formation of associations geared towards the welfare of forklift operators and related parties.

The US Forklift Association(USFA) was started over six decades ago. USFA still carries out its mandate of linking operators with various industry players.

The Fork Lift Truck Association (FLTA) is a similar organisation in the UK founded in 1972. FLTA is the largest representative body in Europe and focuses on safety and productivity.

Looking to Buy or Hire

![Forklifts Hire & Rental prices in Leicester, Northampton, Derby, Warwick, East Midlands, West Midlands, Birmingham and Nottingham]()

a forklift?

With 35+ years of experience, we offer our most competitive rates, flexible finance, 4h service promise & more!

Looking to Buy or Hire

a forklift?

With 35+ years of experience, we offer our most competitive rates, flexible finance, 4h service promise & more!

The Modern Era

Forklift technology has come a long way since the clunky contraptions of the 19th and 20th centuries. Modern forklifts are comfortable and packed with features.

So what are some of the qualities to expect when buying a contemporary forklift?

User Safety

In the mid-20th century, there were many safety concerns raised about forklifts. After much deliberation, new features such as load backrests and overhead guards were introduced.

In the 1980s, engineers introduced ergonomic design, which became a standard feature for the comfort of operators. The drivers now sit in a much safer structure that has a protective shield to prevent accidents. Forklift masts now require a rear support beam for added safety. This feature prevents loads from toppling backward.

Power Sources

The history of forklifts could not have been written without a source of fuel. Luckily, petrol was already being used as motor fuel in the 1890s. Forklifts have advanced from the days of gasoline or diesel-only models.

Nowadays, there are battery-powered versions that operate for hours on one charge. Electric-powered forklifts are just as powerful as gas-operated ones and produce less harmful emissions into the environment.

Some modern forklifts are powered by liquid petroleum gas (LPG) or compressed natural gas (CNG).

Tech On-Board

Modern forklifts integrate computer systems that enable operators to execute tasks like barcode scanning and reading RFID chips.

This cutting-edge technology makes it easier to manage inventory and track items.

Extra Comfort

Forklift operators now have the luxury of ergonomic designs that allow them to work longer without getting too exhausted.

Smaller Bodies

In 1954, Lansing Bagnall manufactured the narrow-aisle forklift model, which made it easier to manoeuvre in restricted spaces.

The narrow build was groundbreaking, and it influenced the contemporary look and feel.

Modern forklifts are now designed to operate in smaller storage facilities without compromising speed and load capacity. The new compact designs are efficient and customizable for various locations.

Forklift Trucks Through History: Looking To the Future

We have looked at the past and present of forklifts, but what is the projected advancement of one of the most iconic pieces of industrial machinery?

Automation

Automated material handling is the future of forklift innovation. Just as autonomous vehicles are becoming a reality in the automotive industry, there’s a focus on computerised guidance systems that will operate forklifts without direct human assistance.

The machines will pick, deliver and track loads autonomously using sensors and laser guidance.

Looking to Buy or Hire

a forklift?

With 35+ years of experience, we offer our most competitive rates, flexible finance, 4h service promise & more!

Electric Powered

Forklifts powered by rechargeable battery packs have been around for a while. Soon electric versions will take over as gasoline, LPG, and CNG-powered vehicles are slowly phased out.

Hydrogen-Powered

There’s a growing segment of hydrogen fuel cell-powered forklifts. These eco-friendly machines are gaining popularity due to their environmental advantage over gasoline-powered machines.

Projected Growth

The 2021 global forklift market size stands at $56 billion. This is a staggering figure but what’s even more interesting is that the number is expected to reach $91 billion by 2030.

These figures reveal an impressive growth trend that is expected to almost double in 10 years.

Conclusion

The subject of forklift trucks through history is fascinating. The history of forklifts dates back to as early as 1867. Major improvements have happened over the years leading to a refined piece of machinery that many industries cannot do without.

Whether or not the forklift will sustain technological advancement or be phased out is yet to be known. However, in the near future, we will see improvements in the modern forklift truck as it continues to take evolutionary steps.

You may also like

Contact Angus Lift Trucks

With over 35 years of experience, Angus Lift Trucks provides service, sales, training, and hire forklift services for your projects across the Midlands. Contact us to rent forklifts in Leicestershire, Nottinghamshire, Northamptonshire, Birmingham, Warwickshire, Derbyshire, East Midlands & West Midlands.

This post is also available in:

Français

Deutsch

Italiano

Português

Español

Български

Hrvatski

Eesti

Latviešu

Lietuvių

Polski

Português

Русский

Slovenčina

Slovenščina

Türkçe

Українська

Albanian

Čeština

Dansk

Nederlands

Ελληνικά

Magyar

Română