A forklift is an indispensable tool in any warehouse operation. They save time and money and make the work process more efficient.

This article will help explain how forklift attachments can help improve your warehouse operations. We will also provide details on the types of forklift attachments available today and what kind of job they do.

Start by listening to our podcast episode on how forklift accessories and attachments increase worker productivity in warehouses:

What Forklift Attachments Accomplish

Tools that empower workers to do more work more quickly and safely can improve the overall efficiency of an operation. Forklift attachments often improve efficiency, accuracy, and safety when they are employed correctly.

Productivity

The entire point of using a forklift is to expedite work and get more done than can be accomplished by manpower alone. Forklifts make work easier, rather than workers being required to hand-load or transport materials. Attachments to forklifts improve upon those efficiencies and productivity.

A forklift attachment lets a forklift shift from one task to another with little transition. This feature saves time and eliminates the need for multiple forklifts to work on one job.

Safety

Forklifts are relatively safe to use with the proper training. However, there is still a risk that a worker could get injured if the machine is not oriented correctly to complete a job from start to finish. Attachments can be useful to make the operation safer in that they are designed to perform specific tasks.

Fewer Costs

With increased productivity comes decreased labour costs. With attachments, one forklift can be multi-tasked to cover several jobs, eliminating the need for additional forklifts. The reduction in the number of necessary machines reduces both labour and inventory costs, maintenance needs, and repair costs.

Seamless Transitions

With the right attachments, a forklift can offload a truck or move pallets of goods and then easily switch to perform other work. Forklift attachments are easy to transition, which means work that used to take two forklifts to finish often only requires one. This means less time is used by workers to finish complex, multi-step processes.

Multi-Purpose Forklift Attachments

Most forklift attachments play more than one role in a typical workday. A driver can also use attachments to raise pallets to upper levels of shelving and then provide a platform for workers to organise and sort equipment, materials, and parts.

A forklift with a boom, for example, can quickly and safely transport materials within a workspace from one point to another by other attachments like a hook or a jib. A forklift with a plough can use that attachment to help lift awkward or bulky objects.

Specific Forklift Attachments

Many different forklift attachments make work easier and safer and help get the job completed more quickly. Here are a few equipment attachments that most forklifts will use.

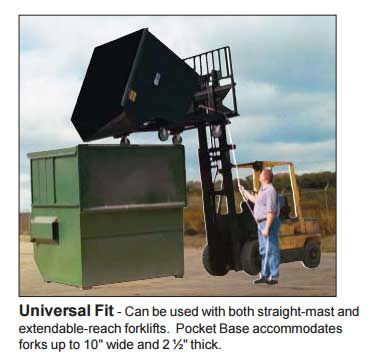

Self-Dumping Hopper

The self-dumping hopper lifts and moves heavy materials and garbage. These attachments can be invaluable if you need to clean up a great deal of clutter. Self-dumping hoppers also have several safety features that prevent the hopper from spilling or dropping its load at the wrong time.

Boom Extension

Booms turn your forklift into a crane. A crane lifts and relocates heavy objects from point A to point B. Some booms extend to 144 inches and can hoist over 5,000 pounds. The compactness of the extension also allows easier transport of materials in a tight space.

Positioners

Positioners let the operator adjust the forks to meet the size of the load. More precise adjustments let the forklift load and offload more quickly. Additionally, positioners reduce the damage done to the forklift tongs and carriage as well as to pallets and the materials stored on the pallets.

Side Shifters

If you have to move materials from side to side, a side shifter is a time and space saver. You can move materials horizontally, allowing the operator to position the forks accurately without moving the entire machine or repositioning a load.

Clamps

Clamps are ideal for moving materials not stored on a pallet. There are an array of clamp options, including, but not limited to:

Bale Clamps

These handle baled materials like waste paper, recycled plastics, scrap metal, and wood. These are often used in junkyards or waste treatment facilities.

Pipe Clamps

Pipe clamps grasp piping, often several at once. Generally, pipe clamps get used in outdoor warehousing situations or an indoor warehouse that is very large.

Drum Clamps

Drum clamps grab drums and secure them upright between two clamping arms. A drum clamp moves large drums filled with chemicals or other liquids.

Paper Roll Clamps

Paper roll clamps move large paper rolls with adjustable clamp pressure to keep the paper rolls intact. The attachment has split clamps that allow the management of two rolls even if they are not the same diameter.

Appliance Clamps

Appliance clamps securely move refrigerators and stoves. With any forklift appliance clamps, the key is to match the clamp you need so you are not trying to force a fit. Clamps are great for warehouses, construction sites, and agricultural operations because they allow large items to be securely fastened to the forklift for transport with minimal effort.

Looking to Buy or Hire

a forklift?

With 35+ years of experience, we offer our most competitive rates, flexible finance, 4h service promise & more!

Hooks

Hooks for a forklift work the same way they work for a crane. Moving heavy objects becomes simple and safe. There are many hook options, ranging from very small to large, which means you can transport just about anything easily and quickly.

Work Platform

Safety is a priority in most warehouses, especially if the work involves heavy items or hazardous materials, shelving, or bulky pallets. A work platform lets your workers do jobs that would otherwise require stairs, ladders or improvised platforms without worrying about accidents or injuries. There are many different work safety platforms, including those that have:

- Rails and cage panels

- Open space for working

- Shelving

- Work stations

A work platform’s most vital function is to protect workers against falls when they work above the ground level. Warehouses employ these for maintenance operations or non-routine work, unless they own a forklift that has an integrated platform.

Dual Pallet Handler

One of the most efficient and productive attachments that can be added to a forklift is a dual pallet handler or single-double pallet handler. It provides a wide range of benefits, not the least of which is being able to lift both single and double pallets.

The four forks on the handler are adjustable and interchangeable, which allows for quick adaptation based on the volume of pallets that you need to move. Switching the forks out or modifying them is a process that takes minutes. Using a single-double-pallet configuration reduces the potential for spills or even dropping an entire pallet.

These work particularly well in work environments with a fast turnover with many units that must be moved. An example of the ideal double-pallet work environment is transporting pallets of liquid or bulky materials, such as rock salt.

Push/Pull Attachments (Slip Sheets)

A push/pull attachment grips slip sheets, which are often just cardboard mats, and pulls the product onto the forks and into the desired location. These work well in distribution centres that do not utilise pallets. The alternative for this attachment is often to unload and load the goods in question by hand, requiring multiple workers and taking significant time to complete.

Layer Picker

A layer picker clamps all four sides of a load, ensuring nothing spills out. It is primarily used for moving canned and bottled goods. It can move single or multiple layers of product on a pallet or the entire pallet. It is also very good for building mixed pallets.

Carpet Poles

These are also called rams. They are long poles that are centred on the carriage of the forklift. The pole is run through the tubing in carpet or textile flooring. They are used to transport rolls of flooring around a warehouse as well as to help unload and load them off and on trucks.

Rams are beneficial in many ways. They help protect the carpet and vinyl flooring. They reduce the need for workers to hoist the rolls of flooring themselves, and they are very useful when loading onto trucks, particularly if multiple loads of flooring are included.

Jibs

A jib is a hooked point that slides onto the forklift carriage. It is used to move or lift non-palletized loads. Using jibs saves manpower versus loading and unloading a non-palletized load by hand. It also reduces the possibility of injuries from workers moving a load by hand.

Rotators

A rotator allows the forklift operator to lift and dump loads with a range of motion from 180 to 360 degrees. This greatly reduces the amount of space needed to manoeuvre products around a warehouse.

Block Forks

These are also called 4-CMU Cubing Forks. A block forklifts and transports cinder blocks and other materials with a “fork” or “tine” design.

You May Also Like

Final Thoughts

Forklift attachments can make work easier, safer, and quicker. Knowing what kinds of attachments are available on the market and how they work will help you understand what you need to streamline your warehouse processes. Finally, at Angus we pride ourselves with over 35 years of experience in forklift sales, hire, training, or repair services across Midlands and the UK, and we always provide our most competitive prices in Leicestershire, Northamptonshire, Birmingham, Warwickshire, Nottinghamshire, Derbyshire, East Midlands, and West Midlands

This post is also available in:

Français

Deutsch

Italiano

Português

Español

Български

Hrvatski

Eesti

Latviešu

Lietuvių

Polski

Português

Русский

Slovenčina

Slovenščina

Türkçe

Українська

Albanian

Čeština

Dansk

Nederlands

Ελληνικά

Magyar

Română